MANUFACTURING

Hopnic Laboratory's manufacturing, driven by sound technology

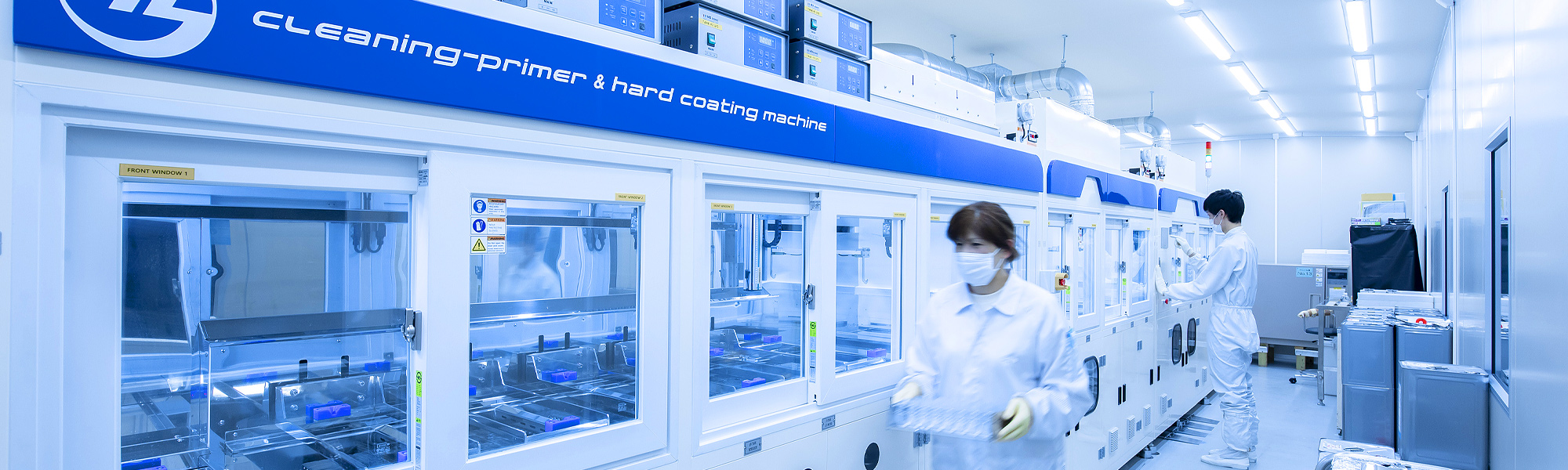

End-to-End Production Delivering High-Quality Products

Typically, manufacturers of polarized lenses procure polarized films from external film manufacturers.However, by handling everything from polarized film production to lens manufacturing in-house, we ensure better alignment and superior quality.

End-to-End Production Delivering High-Quality Products

Typically, manufacturers of polarized lenses procure polarized films from external film manufacturers.However, by handling everything from polarized film production to lens manufacturing in-house, we ensure better alignment and superior quality.

Meeting Clients' Delivery Deadlines

We control our inventory at an optimal level to meet requests for small batch portion and short lead times

We control our inventory at an optimal level to meet requests for small batch portion and short lead times

We are proud to provide superior products in excellent condition to our customers.

We control our inventory at an optimal level to meet requests for small batch portion and short lead times

We are proud to provide superior products in excellent condition to our customers.

Manufacturing of Customized Products Based on Clients' Applications and Purposes

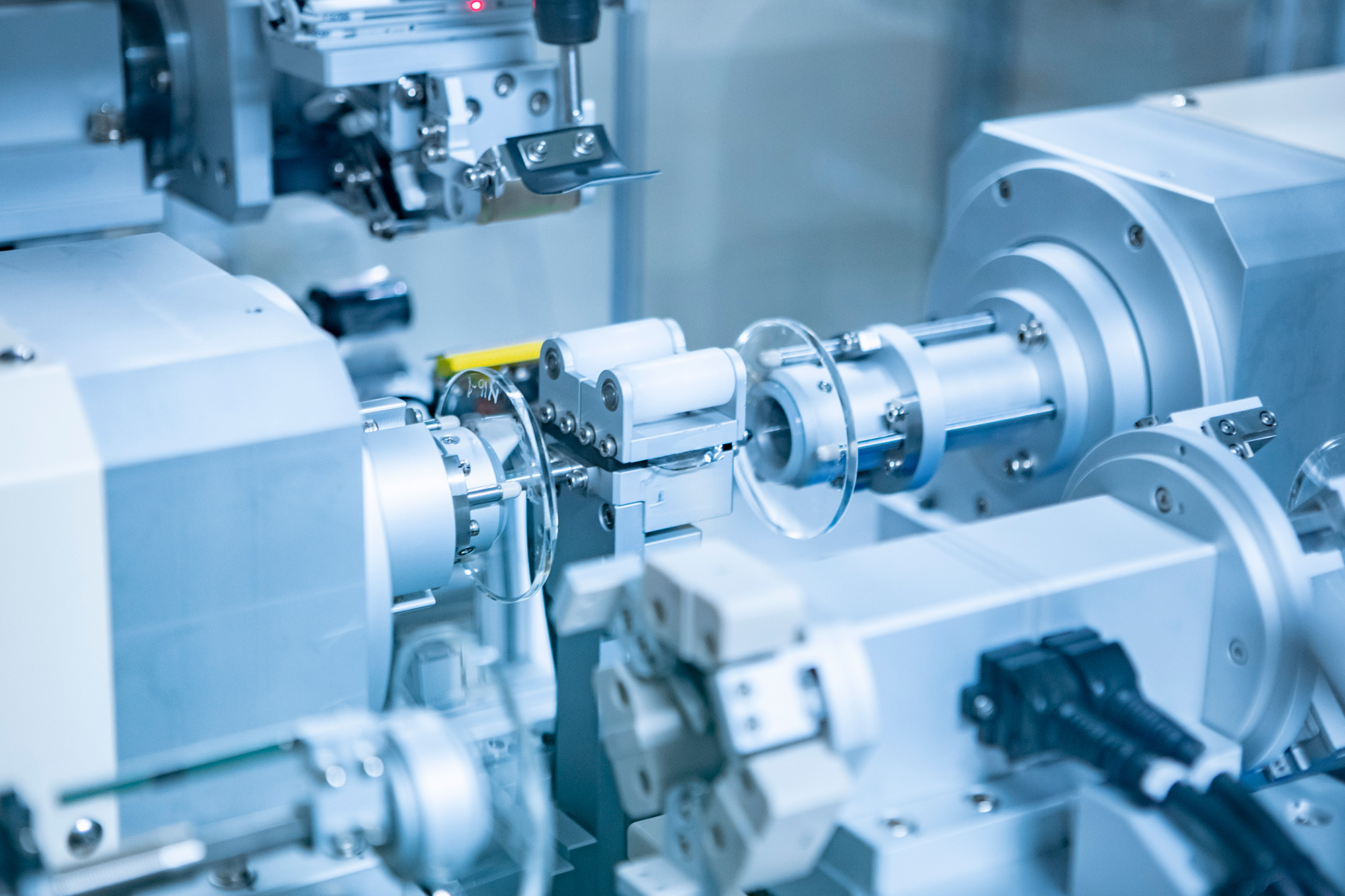

Our meticulous casting process enables us to precisely meet customization requests tailored to specific applications

In addition to our end-to-end production capabilities, our flexibility allows us to incorporate and deliver the customizations and arrangements our customers seek

In addition to our end-to-end production capabilities, our flexibility allows us to incorporate and deliver the customizations and arrangements our customers seek

Manufacturing of Customized Products Based on Clients' Applications and Purposes

Our meticulous casting process enables us to precisely meet customization requests tailored to specific applications

In addition to our end-to-end production capabilities, our flexibility allows us to incorporate and deliver the customizations and arrangements our customers seek

In addition to our end-to-end production capabilities, our flexibility allows us to incorporate and deliver the customizations and arrangements our customers seek

Lenses encompass medicine, optics, and chemistry

Why Hopnic Laboratory is a research-oriented manufacturer...

We started our company with a heartfelt desire to alleviate the challenges faced by everyone in need of lenses and to provide a comfortable visual environment.

That is why we focus on every need and listen to customer feedback. In response, we research materials, develop functional films, and apply coatings. Our goal is to enhance individual employee's skills and understanding on the manufacturing floor. Quality improvement in R&D is crucial to meeting customer needs, so we continually exchange ideas with experts in ophthalmology, engineering, and chemistry to enhance our development capabilities.

As a result of our activities, Hopnic Laboratory has been selected as one of the "Global Top 100 Niche Companies" and acquired numerous patents, including international patents.

We started our company with a heartfelt desire to alleviate the challenges faced by everyone in need of lenses and to provide a comfortable visual environment.

That is why we focus on every need and listen to customer feedback. In response, we research materials, develop functional films, and apply coatings. Our goal is to enhance individual employee's skills and understanding on the manufacturing floor. Quality improvement in R&D is crucial to meeting customer needs, so we continually exchange ideas with experts in ophthalmology, engineering, and chemistry to enhance our development capabilities.

As a result of our activities, Hopnic Laboratory has been selected as one of the "Global Top 100 Niche Companies" and acquired numerous patents, including international patents.

Interviewing our R&D team members

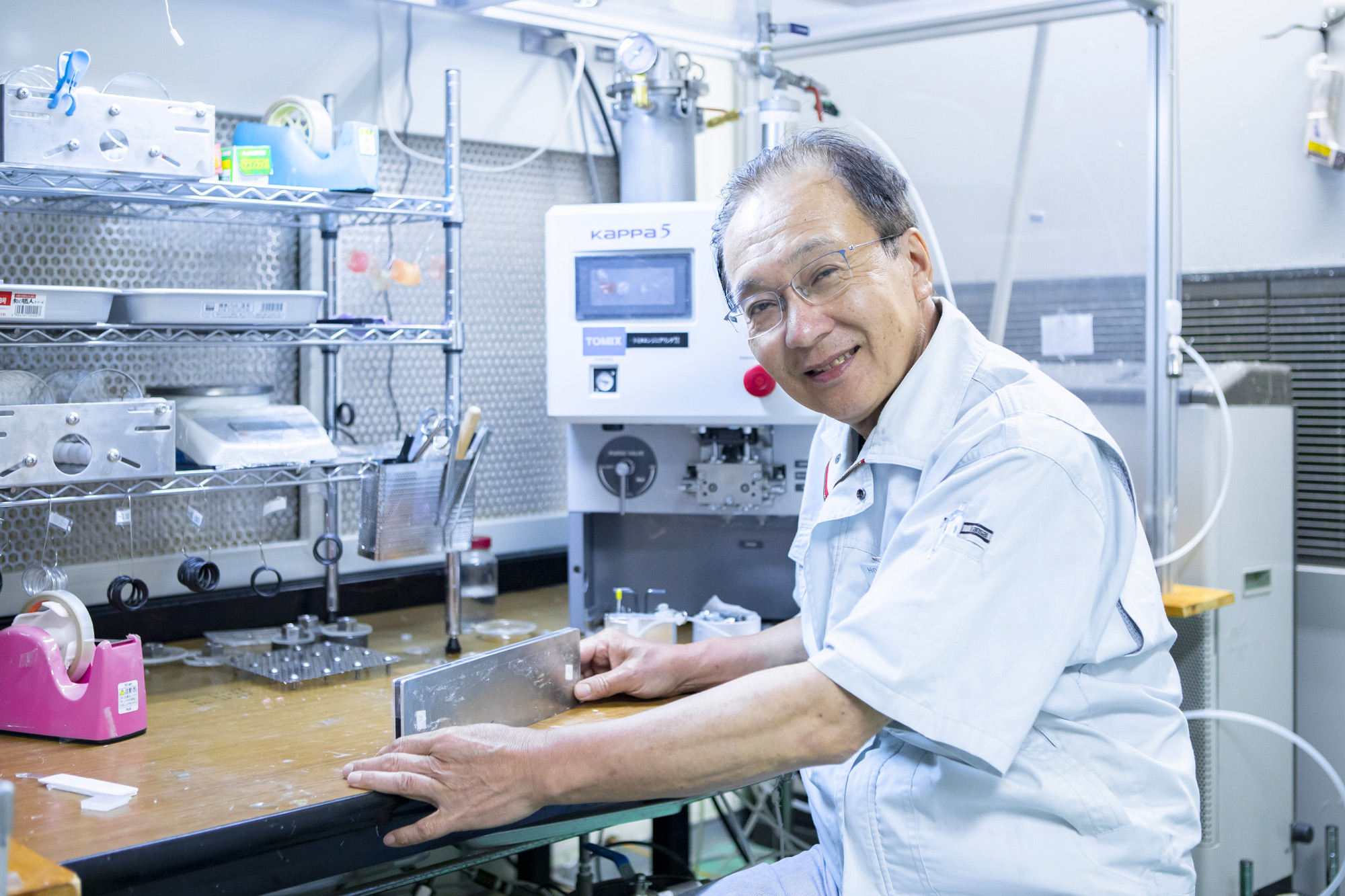

Founding member, ex-Head of Technology and Development(Retired)

Yoshimitsu Sagara

Advancing our proprietary technology

I have been engaged in research and development at Hopnic Laboratory for many years, during which I obtained patents in both Japan and the United States for low vision lenses.

The technology can be applied not only to assist individuals with low vision but also to correct presbyopia and result, it is utilized in various lenses at our company.

I have now stepped back from the front lines, entrusting my responsibilities to the next generation, and I support Hopnic Laboratory on a request basis. I hope our company continues to provide a comfortable visual environment to more people.

The technology can be applied not only to assist individuals with low vision but also to correct presbyopia and result, it is utilized in various lenses at our company.

I have now stepped back from the front lines, entrusting my responsibilities to the next generation, and I support Hopnic Laboratory on a request basis. I hope our company continues to provide a comfortable visual environment to more people.

Research and Development Department

Hayaki Matsuda (Joined in 2016)

Gaining more and more experience

"I began working in the Research and Development Department in my fourth year with the company, in 2020. My role involves researching and developing methods to turn our customers' desires for new products into reality and ultimately bringing those products to market.

Since my early years with the company, I have been involved in research and development, which has allowed me to build a solid foundation of knowledge and experience. Now, I am focused on achieving the goal of creating entirely new technologies and products. While this is challenging work, it is incredibly fulfilling."

Since my early years with the company, I have been involved in research and development, which has allowed me to build a solid foundation of knowledge and experience. Now, I am focused on achieving the goal of creating entirely new technologies and products. While this is challenging work, it is incredibly fulfilling."

Production process

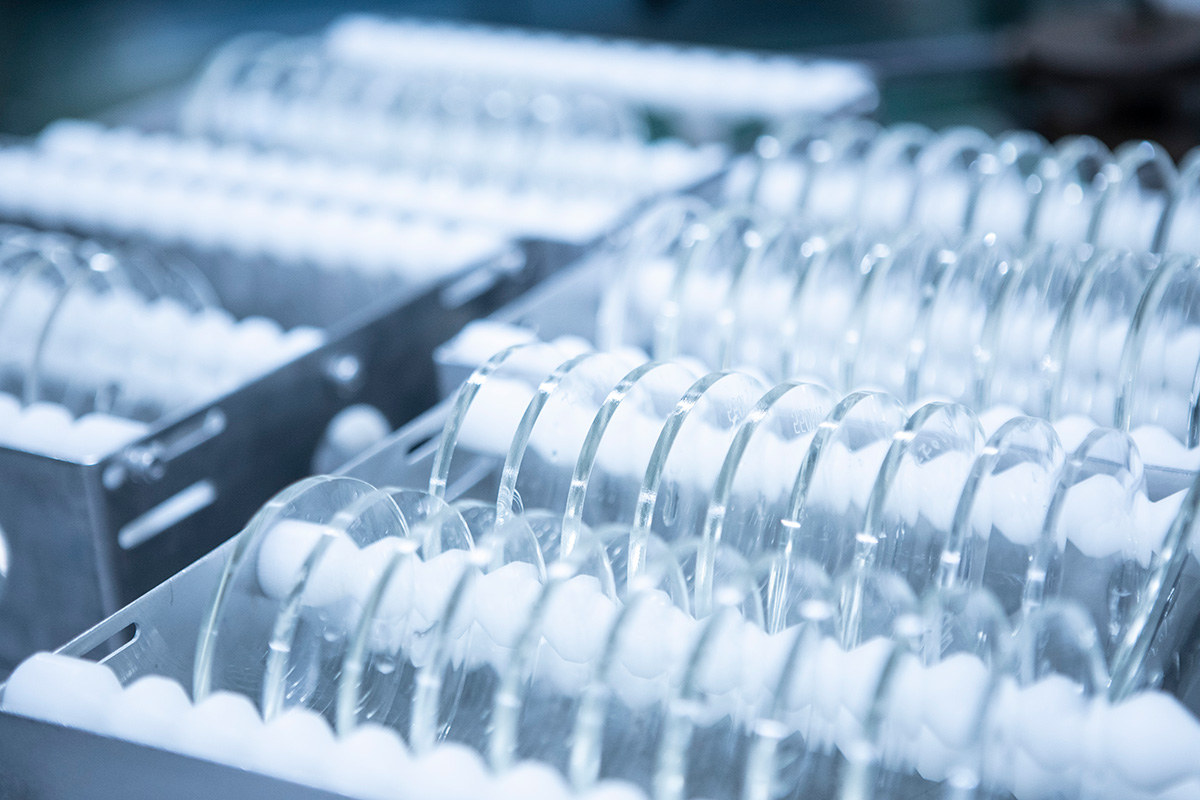

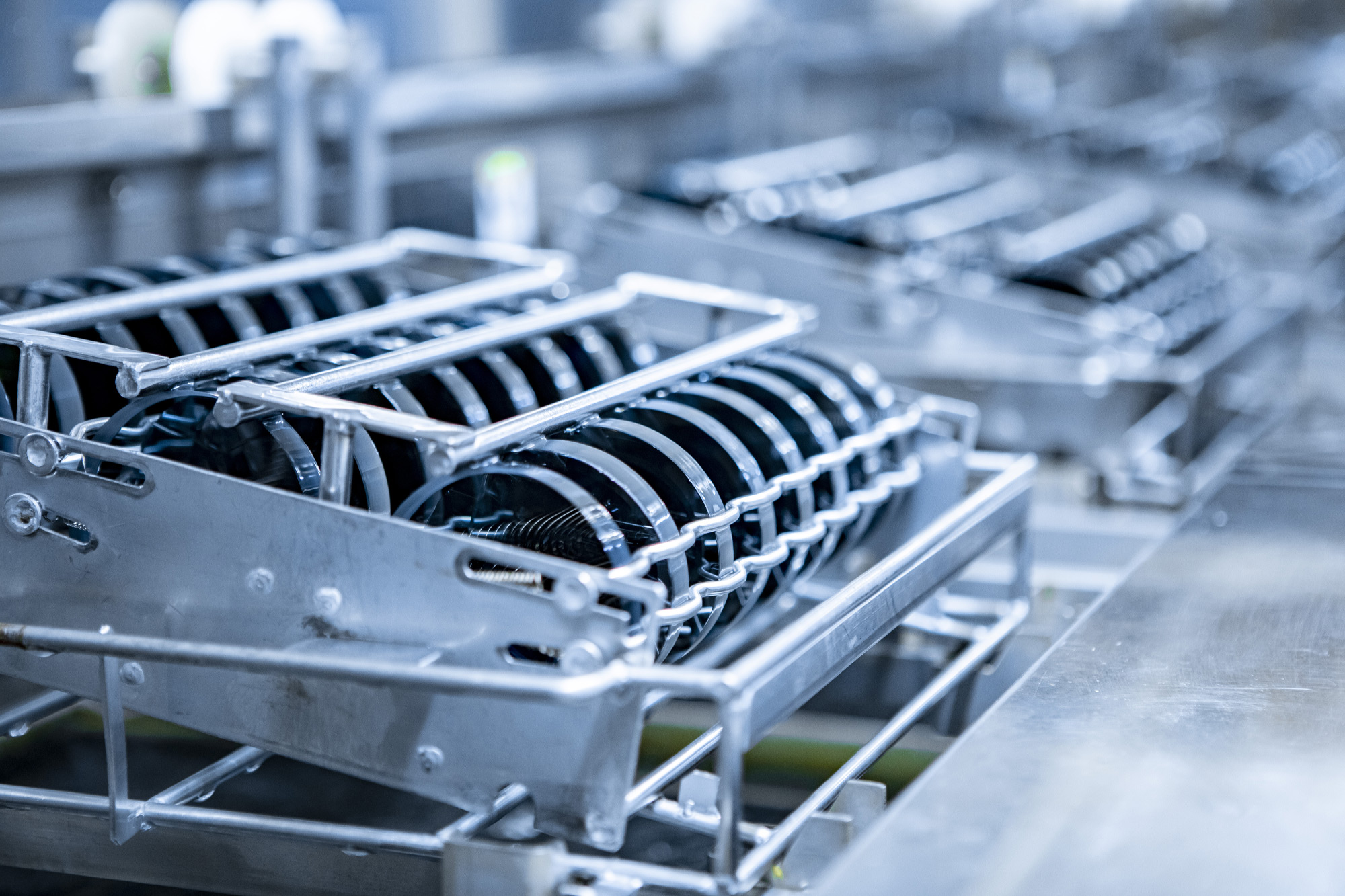

Manufacturing and processing of polarizing films

Dyeing base PVA (Polyvinyl Alcohol) films. This process forms the essential foundation for our world-leading high refractive index polarizing lenses.

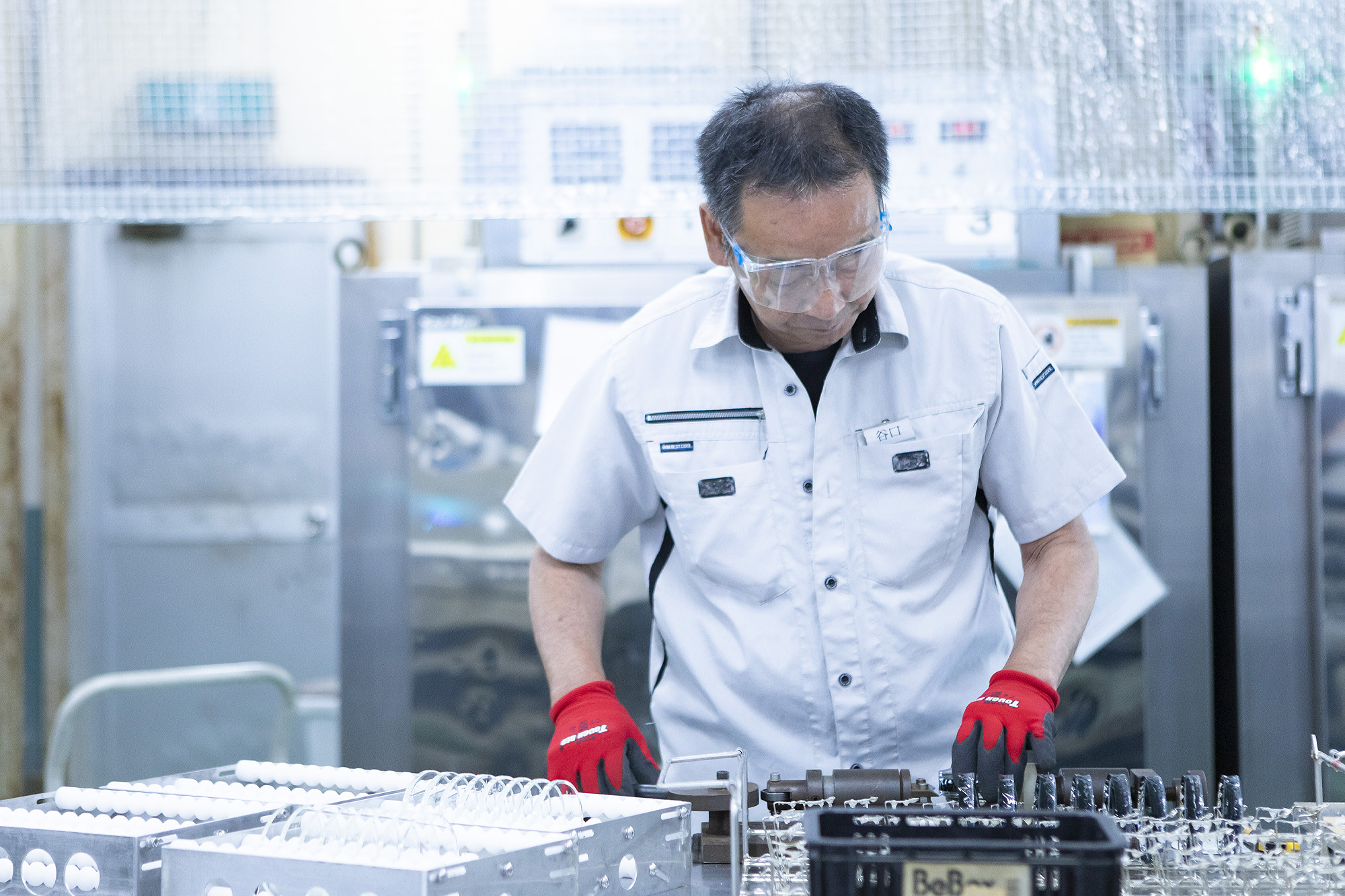

Mixing and filling of raw materials

We custom formulate raw materials for lens substrates according to their intended use and purpose. These materials are then filled into glass molds. This is a delicate process where any contamination by dust or air bubbles can result in defective products.

Polymerization and demolding

The molds filled with raw materials are cured through a chemical reaction and heating process. During the polymerization process, precise temperature control is required for 16 to 72 hours. Once the lenses have hardened, they are removed from the molds and gradually cooled.

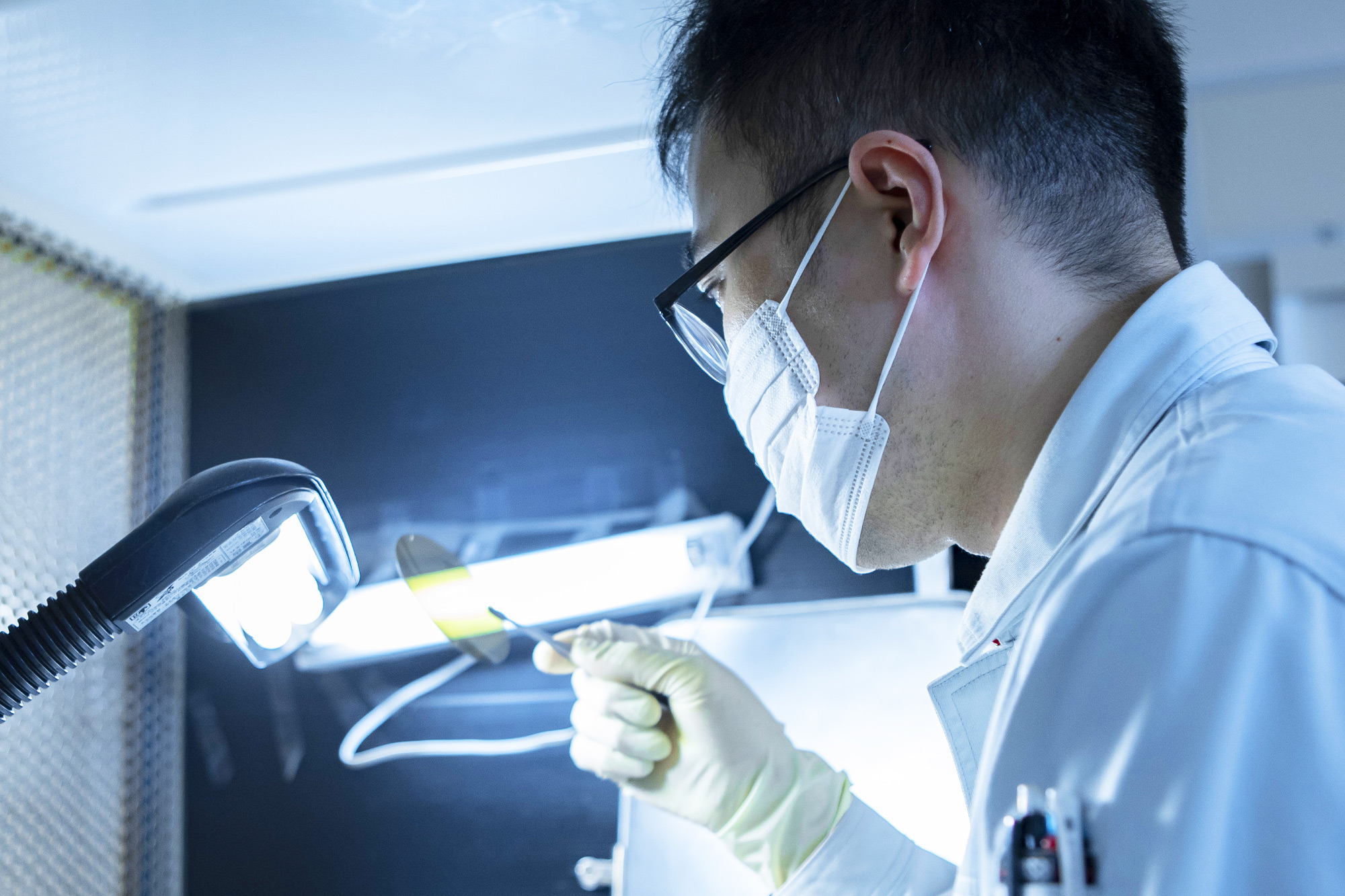

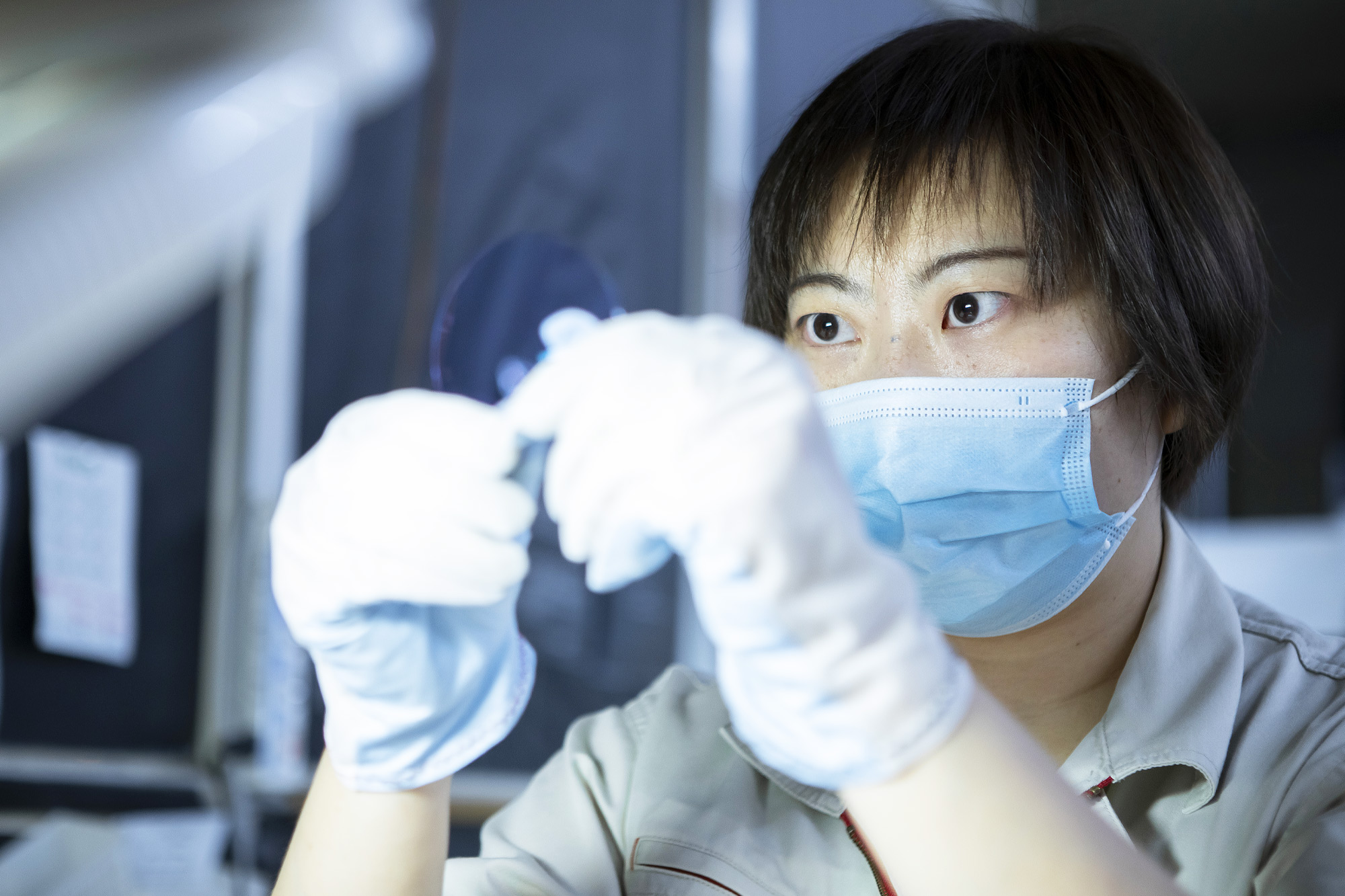

Quality inspection

Experienced inspectors, using inspection equipment, check for scratches and chips, as well as lens surface accuracy, optical precision, appearance quality, and polarization degree.